- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

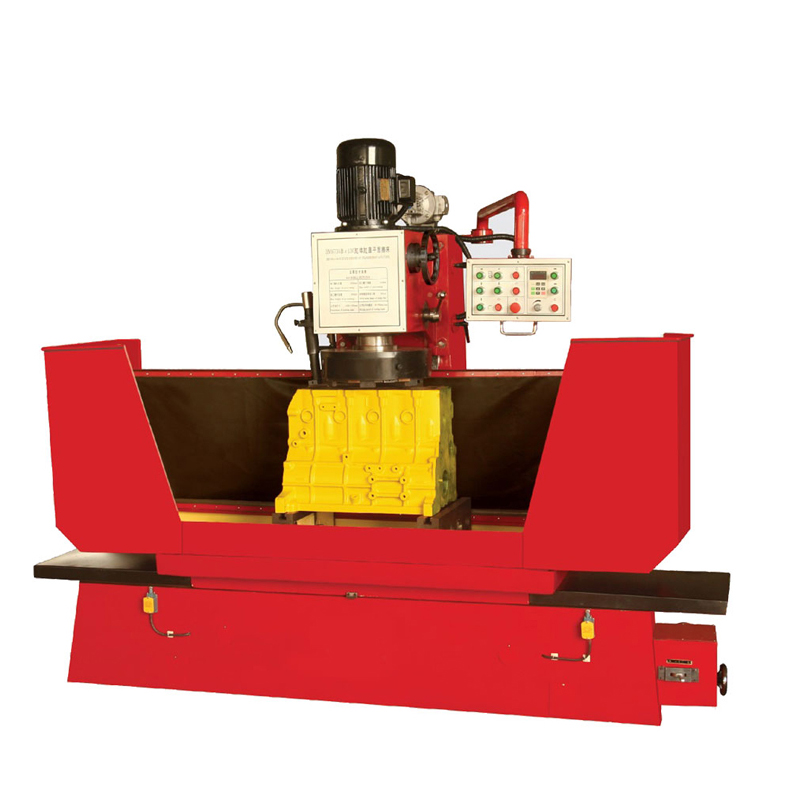

Umshini Wokugaya I-Cylinder Block & Milling 3M9735A

Izici:

I-Cylinder Block Grinding& Umshini Wokugaya

1. Umshini usetshenziselwa kakhulu ukugaya nokugaya indawo yokuxhuma phakathi kwesilinda somzimba nekhava yesilinda yayo yonke injini (yezimoto, ogandaganda, amathangi nemikhumbi).

2. Ngenxa yokuthi injini izosetshenziswa isikhathi eside, indawo yokuxhuma yesilinda yomzimba kanye nekhava yesilinda izoshintsha futhi injini izosebenza ngokujwayelekile.

3. Ukunemba kokusebenza kungafinyelelwa ukuthi indawo yokuxhuma yomzimba wesilinda kanye nesembozo se-cylinder kugaywe noma kugaywe.

4. Umshini ungakwazi futhi ukugaya ingaphezulu kwezinye izingxenye uma i-chuck kagesi ifakwe.

5. Umshini uthatha (1400/700r/min) motor enamagiya amabili angu-1400r/min usetshenziselwe ukugaya ubuso besilinda somzimba noma ikhava yesilinda, esenziwe ngezinto ezisansimbi. Futhi i-700r/min isetshenziselwe ukugaywa indawo engaphezulu eyenziwe ngezinto ze-aluminium. I-Emery wheel feeding yenziwa ngesandla. I-Emery wheel feed 0.02mm ngesikhathi sesondo lesandla lizungezisa i-lattice engu-1. I-Pulley isebenzisa ngokuthulula ukwenza i-spindle eyinhloko isebenzise isikhathi sokusonteka kuphela.

6. Ithebula elisebenzayo lethuluzi lomshini likhetha futhi lisebenzisa idrayivu yemoto kagesi engu-Y801-4 ngokuzungezisa, ekubhekeni kobuso bomsingathi, i-potentiometer whorl twist kanye nokuthola isivinini sokuphakelayo esifanele, okulula ukusisebenzisa okuthembekile.

Imininingwane Yezobuchwepheshe:

| Imodeli | 3M9735Ax100 | 3M9735Ax130 | 3M9735Ax150 |

| Usayizi osebenzayo (mm) | 1000x500 | 1300x500 | 1500x500 |

| Ubukhulu. ubude bokusebenza(mm) | 1000 | 1300 | 1500 |

| Ubukhulu. ububanzi bokugaya(mm) | 350 | 350 | 350 |

| Ubukhulu. ubude bokugaya(mm) | 600 | 600 | 800 |

| Ukuhamba ngebhokisi le-spindle(mm) | 800 | 800 | 800 |

| Inani lamasegimenti(ucezu) | 10 | 10 | 10 |

| Isivinini se-spindle(r/min) | 1400/700 | 1400/700 | 1400/700 |

| Ubukhulu bebonke(mm) | 2800x1050x1700 | 2650x1050x2100 | 2800x1050x2100 |

| Ubukhulu bokupakisha(mm) | 3100x1150x2150 | 2980x1150x2200 | 3200x1150x2280 |

| NW/GW(T) | 2.5/2.8 | 2.8/3.0 | 3.0/3.3 |