Welcome to our websites!

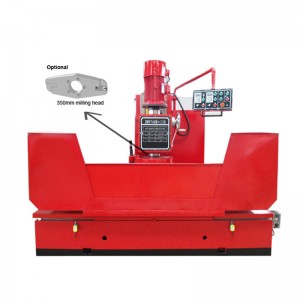

Vertical Fine Boring-Milling Machine T7240

Features:

1. The machine is mainly use for boring large and deep holes(such as cylinder body of locomotive, steamship, car), also can milling the surface of the cylinder.

2. Servo-motor control the table longitudinal move and the spindle up and down, Spindle rotation adopts variable-frequency motor to adjust the speed, so it can achieve the stepless speed change regulating.

3. Electricity of the machine are designed for PLC and man-machine interaction.

| Model | T7240 | |

| Max.boring diameter | Φ400mm | |

| Max. boring depth | 750mm | |

| Spindle carriage travel | 1000mm | |

| Spindle speed (stepless speed change for frequency conversion) | 50~1000r/min | |

| Spindle feed move speed | 6~3000mm/min | |

| Distance from spindle axis to carriage vertical plane | 500mm | |

| Distance from spindle end-face to table surface | 25~ 840 mm | |

| Table size L x W | 500X1600 mm | |

| Table longitudinal travel | 1600mm | |

| Main motor ( Variable-frequency motor) | 33HZ,5.5KW | |

| Machining accuracy | Boring dimension accuracy | IT7 |

| Milling dimension accuracy | IT8 | |

| Roundness | 0.008mm | |

| Cylindricity | 0.02mm | |

| Boring roughness | Ra1.6 | |

| Milling roughness | Ra1.6-Ra3.2 | |

| Overall dimensions | 2281X2063X3140mm | |

| N.W/G.W | 7500/8000KG | |