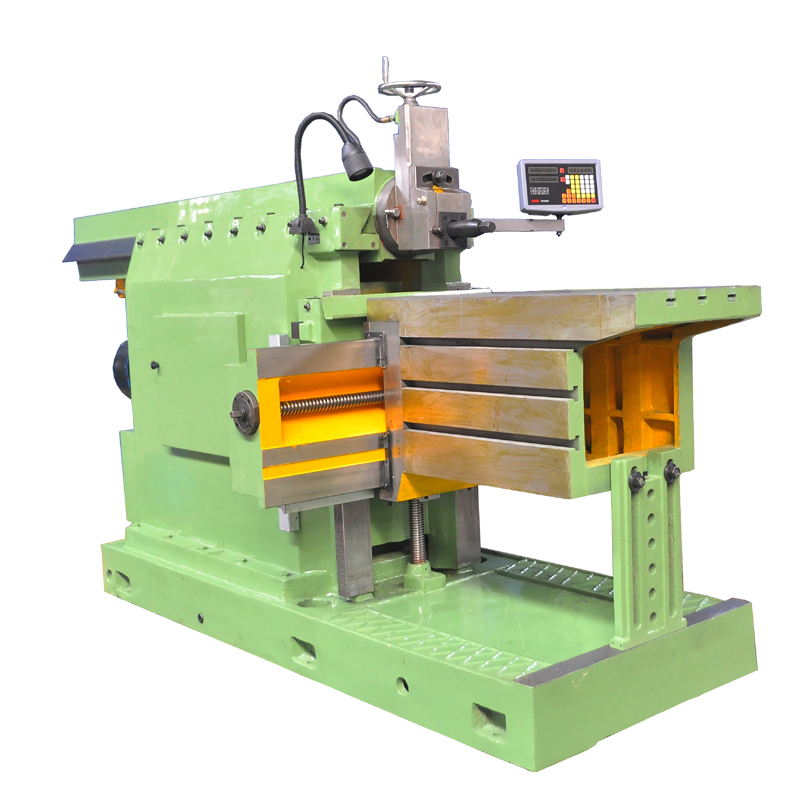

Super Lowest Price Horizontal Lathe - Shaper Machine BY60100C – Hoton

Super Lowest Price Horizontal Lathe - Shaper Machine BY60100C – Hoton Detail:

SHAPING MACHINE

1.The machine is used in a variety of cutting and forming flat surface, suitable for single and small batch production.

2.Bed and other key parts of tempering, vibration aging, super audio quenching heat treatment process, makes the machine more stable accuracy, longer service life.

3.The principal cutting movement and feed movement are the hydraulic transmission, stepless speed regulation, with hydraulic overload protection device, smooth rotation, little overrun, start and stop is flexible and reliable, rigidity, cutting force, high directional accuracy, low temperature, small thermal deformation and precision stability, and can apply to the work of a strong and continuous cutting.

4.The machine tool can achieve rapid horizontal and vertical movement, turret with automatic tool lifting mechanism, machine tool handles, easy to operate, high degree of automation

SPECIFICATIONS:

|

MODEL |

BY60100C |

|

Maximum cutting length(mmin) |

1000 |

|

Cutting speed of ram(mm/min) |

3-44 |

|

Distance from lower edge of ram to upper surface of table(mm) |

80-400 |

|

Max.cutting force(N) |

28000 |

|

Max.travel of tool head(mm) |

160 |

|

Maximum size of tool shank(W×T)(mm) |

30×45 |

|

Upper working surface of table(L×W)(mm) |

1000×500 |

|

Width of central T-slot of table(mm) |

22 |

|

Max.horizontal travel of table(mm) |

800 |

|

Horizontal feed of table per recip rotating stroke of ram(stepless) (mm) |

0.25-5 |

|

Main motor(kw) |

7.5 |

|

Motor for rapid motion of table(kw) |

0.75 |

|

Overall dimensions(L×W×H)(mm) |

3615×1574×1760 |

|

N.W/G.W(kg) |

4200/4350 |

Product detail pictures:

Related Product Guide:

Reformed drug addict says young girls offered drugs outside school | Jyp260

Understanding Laser Cutting | Cnc-Controlled Flatbed Lathe

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers' requires for Super Lowest Price Horizontal Lathe - Shaper Machine BY60100C – Hoton , The product will supply to all over the world, such as: Netherlands, Canberra, Cyprus, "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, please feel free to contact us. We hope to establish cooperative relationships with you in the near future.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.