- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

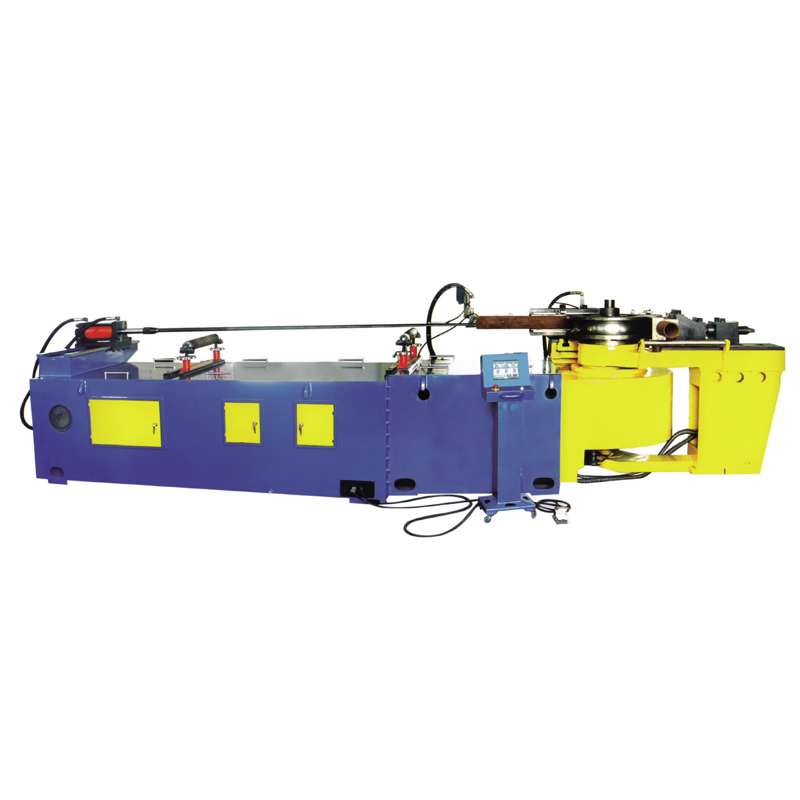

single pipe bending machine DW168/219/325/400NC

ECHINICAL CHARACTERISTICS:

The microcomputer control is adopted with strong functions,high extensibility,English subtitles and dialogue-based operation,easy to learn and understand,Set speed by segmentation with high precision of elbow pipes,The sixteen level elbow pipe data setting and storage,and remarkably smooth assembly of work pieces of many angles,The function of reloading with auxiliary shoving and slowing returning the core can beachieved,The thin-wall pipes can be bent and manufactureed.Extensively used in large ship building and repair,boiler,petroleum pipeline and auto spare parts.

|

Model |

||||

|

Min bending R for carbon pipe is :1.5D |

∅168×14.0t |

∅219×18.0t |

∅325×20.0t |

∅400×22.0t |

|

Min bending R for S.S pipe is :1.5D |

∅135×10.0t |

∅168×10.0t |

∅275×12.0t |

∅325×14.0t |

|

Availability length of bending pipe |

3600mm |

4000mm |

4500mm |

4500mm |

|

Max R for bending |

550mm |

370mm |

1000mm |

1150mm |

|

Max angle for bending |

185° |

185° |

185° |

185° |

|

Bending process for every pipe |

16 |

16 |

16 |

16 |

|

Oil pressure |

14mpa |

14mpa |

14mpa |

14mpa |

|

Electrical motor power |

30kw |

45kw |

55kw |

55/75kw |

|

Weight |

12000kg |

18000kg |

21000kg |

27000kg |

|

Size |

630×250×130 |

690×225×175 |

720×230×180 |

730×230×185 |