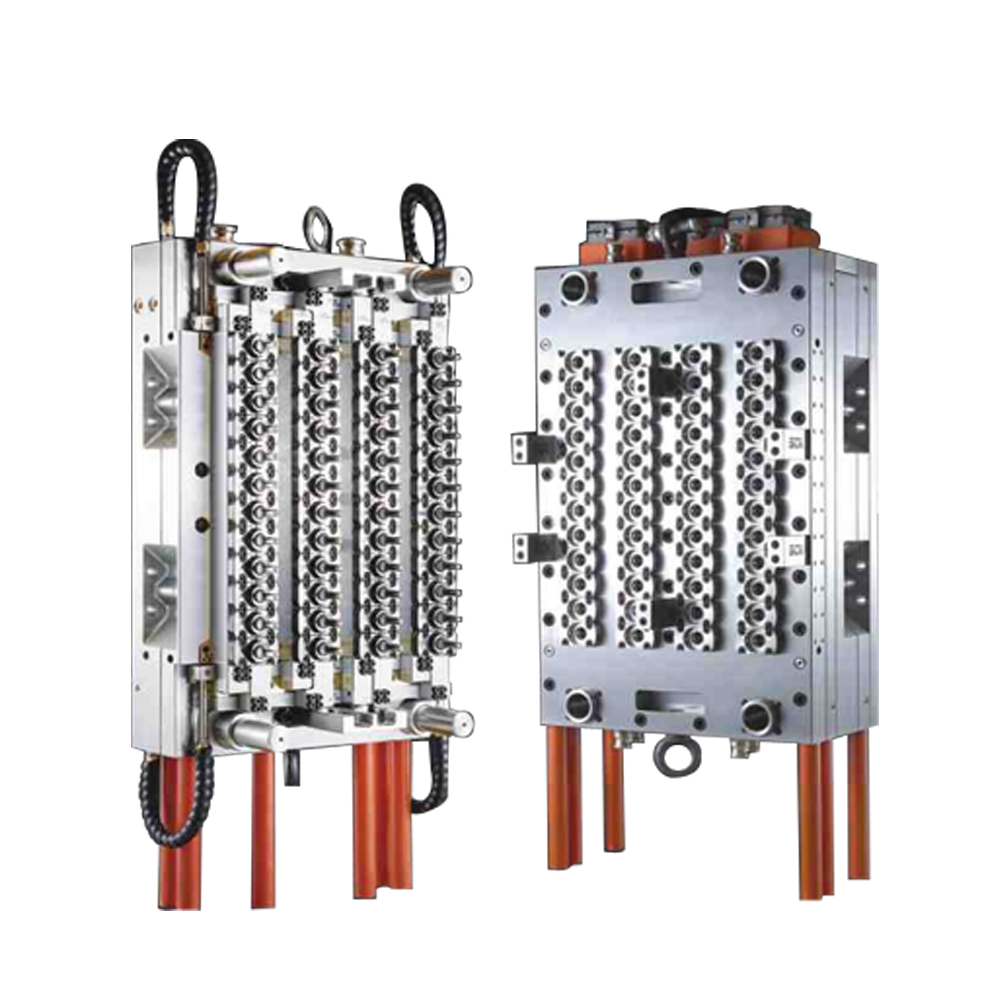

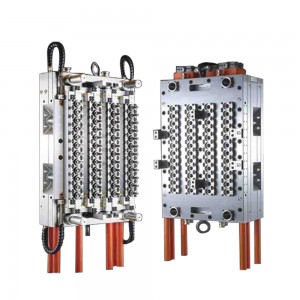

Preform Moulds,Blow Mould,Cap Mould

1.Mold cavity from 1 up to 72.

2. Electric control system with simulating stretch testing improve yield rate.

3. Adopt world advanced dipole taper localization technique, each cavity self-clamp independently, ensure mould concentricity.

4. The material of mould die core and die cavity are made of Sweden special mould steel.

5. International standard screw neck , imported nitrogen steel with high hardness is of long usage.

6. Advanced hot runner design and even heating temperature make sure the high quality of plastic products.

7. Valve gated type without tail reduces labor force.

8. At least 3 million guarantee.

1.We employ state-of-the art CDC / CAM technologies to design and build high-quality tooling.

2.We supply blow mould by customers demand for an increasing variety of markets applications

ranging over wide-mouth jars,cosmetic and detergent bottles , pharmaceutical bottles , soya

sauce and edible oil bottles, double seam can,bottled water heat-resistant bottles, and CSD bottles.

Cap Mould:

We have significant experience in the manufacture of cap moulds for different types of closures by customer's demand.