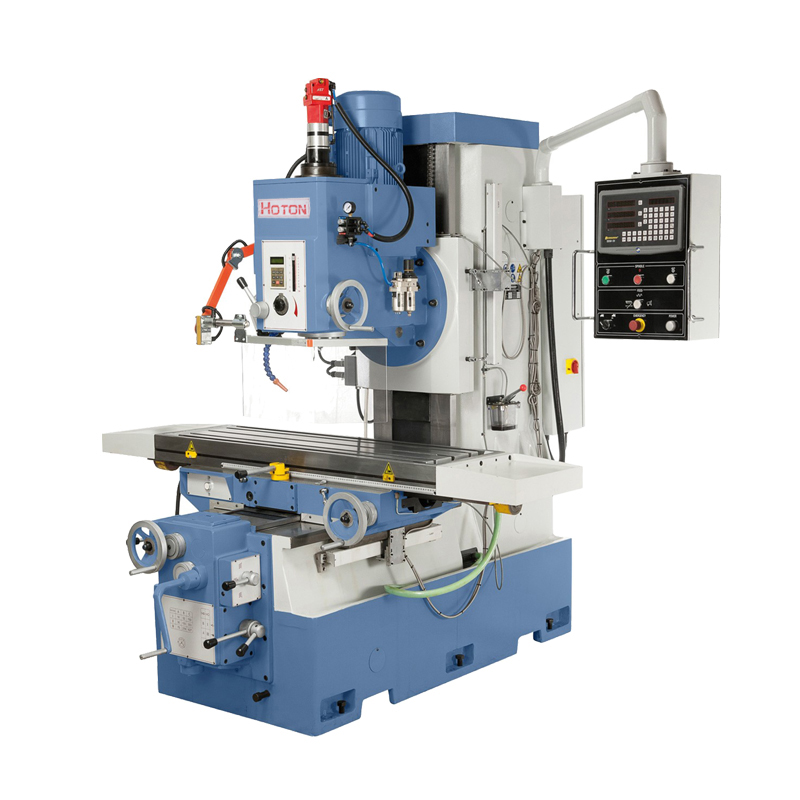

OEM/ODM China Cnc Lathe Tck420 - Vertical Machining Center VMC850 – Hoton

OEM/ODM China Cnc Lathe Tck420 - Vertical Machining Center VMC850 – Hoton Detail:

VERTICAL MACHINE CENTER FEATURES:

1.The fuselage and main components are high strength cast iron, microstructure stability, ensure the

stability of machine tool for long-term use.

2.The column at the bottom of A type bridge type structure, combined with the big box base, greatly

reduce the vibration of machine on heavy cutting

3.The pre tension precision ball screw drive

4.The high speed, high precision, high rigidity spindle unit

5.The design of oil-water separation

6.The intermittent automatic lubrication

7.Automatic scraping knife system

Application:

The vertical machining center can be applied to many fields such as mechanical processing and mould

manufacturing, canadapt from roughing to finishing processing requirements, has the characteristics of

high precision, high efficiency, is widelyused in aerospace, military industry, mould, automobile,

internal combustion engines, textile machinery, chemical machinery processing, oil, electronics and other industries.

SPECIFICATIONS:

|

SPECIFICATIONS |

UNITS |

VMC850 |

|

X-axis travel |

mm |

900 |

|

Y-axis travel |

mm |

550 |

|

Z-axis travel |

mm |

550 |

|

Table size |

mm |

1100×500 |

|

Maximum table load |

kg |

500 |

|

T-slot(slot number×width×pitch) |

mm |

5-18-100 |

|

Spindle power |

kw |

7.5 |

|

Maximum spindle speed |

rpm |

8000 |

|

Rapid traverse (X/Y/Z) |

mm/min |

18000 |

|

Cutting feed |

mm/min |

1-6000 |

|

Spindle nose to table |

mm |

130-680 |

|

Spindle center to column surface distance rail |

mm |

540 |

|

Maximum tool diameter |

mm |

Φ130 |

|

Maximum tool length |

mm |

300 |

|

Maximum tool weigh |

kg |

8 |

|

Positioning accuracy |

mm |

±0.008 |

|

Repeat accuracy |

mm |

±0.0075 |

|

Machine weight |

kg |

5800 |

|

Dimensions |

mm |

3600×2360×2500 |

Product detail pictures:

Related Product Guide:

Welcome to the Slow Death of Satellite TV in America | Shearing Machine

Researchers offer new physics rule to find mechanical strain | Cnc-Controlled Flatbed Lathe

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for OEM/ODM China Cnc Lathe Tck420 - Vertical Machining Center VMC850 – Hoton , The product will supply to all over the world, such as: Pakistan, Swiss, Munich, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!