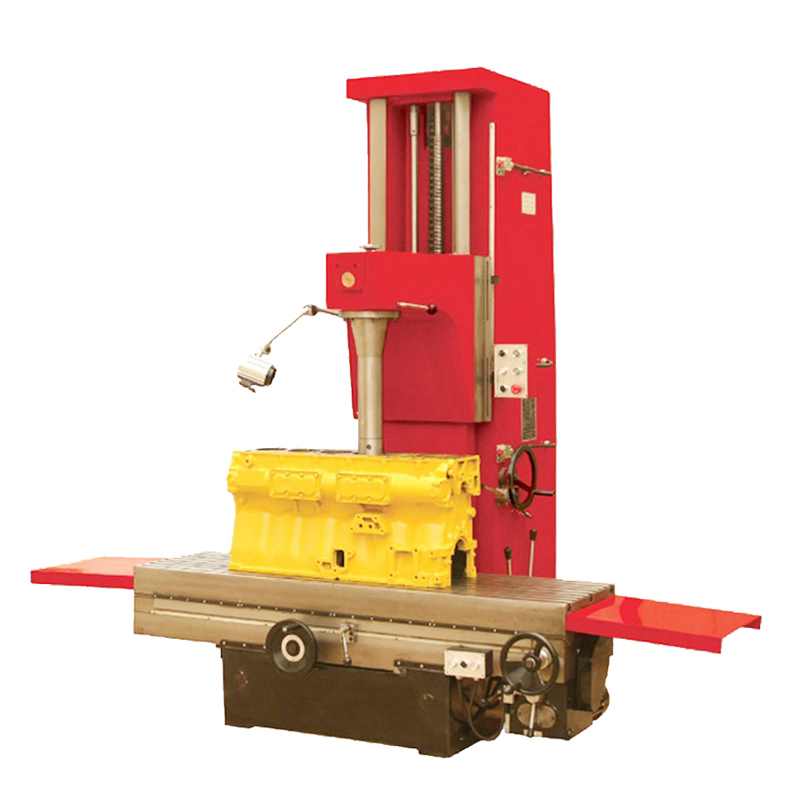

OEM Manufacturer Bench Milling Drilling Machine - Surface Grinder Machine SG60120AHR SG60120AHD – Hoton

OEM Manufacturer Bench Milling Drilling Machine - Surface Grinder Machine SG60120AHR SG60120AHD – Hoton Detail:

SURFACE GRINDER FEATURES:

Headstock runs in preloaded angular ball bearings and features a high load capacity

X and Y axis guide ways are counter-laminated(plastic)

Separate hydraulic unit with oil cool

X axis with high-dynamic, hydraulic drive

Combination of box ways and V-guides on X and Y, plus rectangular guide way on Z

Premium components ensure maximum accuracy for continuous operation

SPECIFICATIONS:

|

SPECIFICATION |

UNIT |

SG50100 AHR/AHD |

SG50160 AHR/AHD |

SG60120 AHR/AHD |

SG60160 AHR/AHD |

SG60220 AHR/AHD |

|

|

Table size |

mm |

500x1000 |

500x1600 |

610x1200 |

610x1600 |

610x2200 |

|

|

Max. grinding (WxL) |

mm |

500x1000 |

500x1600 |

610x1200 |

610x1600 |

610x2200 |

|

|

Max. distance from table to spindle center |

mm |

600 |

|||||

|

Magnetic chuck size (optional equipment) |

mm |

500x1000x1 500x800x2 600x1000x1 600x800x2 600x1000x2 |

|||||

|

Speed of table longitudinal movement |

m/min |

5-25 |

|||||

|

Wheelhead cross movement |

Auto feed |

mm/t |

0.5-20 |

||||

|

Rapid speed |

m/min |

1.25 |

|||||

|

Feed of handwheel |

mm/div |

0.02 |

|||||

|

Wheelhead vertical movement |

Auto feed |

mm/t |

0.005, 0.01, 0.015, 0.02, 0.03, 0.04 (only for AHD model) |

||||

|

Rapid speed |

mm/min |

230 |

|||||

|

Feed of handwheel |

0.002 |

||||||

|

Wheel |

Speed |

Rpm |

1450 (50HZ), 1740 (60HZ) |

||||

|

Size (ODxWxID) |

mm |

355x (20-50) x127 |

|||||

|

Motor of spindle |

kw |

7.5 |

|||||

|

Max. loading capacity of table (include chuck) |

kg |

700 |

880 |

970 |

1230 |

1690 |

|

|

Total rated power |

kw |

12 |

14 |

||||

|

Height of machine |

mm |

2390 (include the packing base) |

|||||

|

Floor space (LxW) |

mm |

4700x2550 |

7120x2550 |

4740x2750 |

5340x2750 |

6740x2750 |

|

|

Gross weight |

kg |

5500 |

6000 |

6500 |

7000 |

8000 |

|

Product detail pictures:

Related Product Guide:

Best of 2018: Marine foam technology lowers refrigerated trailer weights | Hydraulic Ring Bending Machine

August 11th Grand Opening for Skateboard Park : The Prowers Journal | Cnc-Controlled Flatbed Lathe

With our loaded encounter and considerate services, we have now been recognized as a trustworthy supplier for lots of worldwide consumers for OEM Manufacturer Bench Milling Drilling Machine - Surface Grinder Machine SG60120AHR SG60120AHD – Hoton , The product will supply to all over the world, such as: Paraguay, Guatemala, venezuela, We welcome you to visit our company, factory and our showroom displayed various products that will meet your expectation, meanwhile, it is convenient to visit our website, our sales staff will try their efforts to provide you the best service. If you need more information, please do not hesitate to contact us by E-mail or telephone.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.