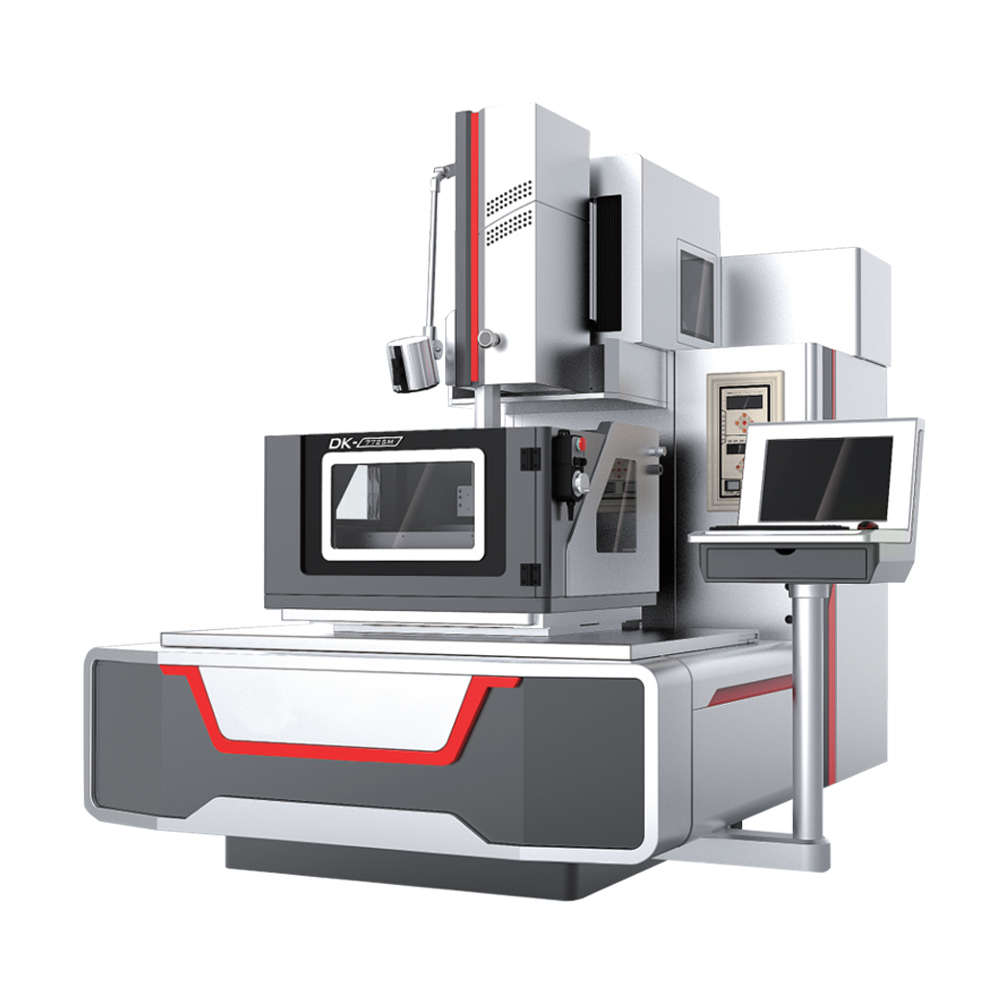

High reputation Lathe Cs6240 - CNC EDM wire cutting machine DK7725M DK7732M DK7740M – Hoton

High reputation Lathe Cs6240 - CNC EDM wire cutting machine DK7725M DK7732M DK7740M – Hoton Detail:

Performance Indicators :

●The structure and casting process of the main body of the machine.

●Max cutting efficiency≥ 200mm2 / min.

●Best surface roughness≤Ra0.8μm.

●X, Y , U,V , Z five axis composes of Taiwan HIWIN linear guide and high precision double nut ball screw rod.

●High precision cuttings≤±2μm.

●Continuous cutting 100,000 mm2 molybdenum wire loss≤0.005mm

●The whole machine adopts the brand bearings imported from Japan.

●The whole electrical components are imported from Germany and Japan , etc .

●Control System can do screw pitch compensation and reverse gap compensation to four axis of X,Y , U , V ,

and compatible with the current market mainstream driving software . With handwheel pulse to control running wire movement instead of

the primitive stroke switch , using encoder to directly control , realizing precise location.

●The use of low speed wire-cutting-type automatic tension structure , to automatically adjust the tension strength with different machining state.

●Low energy-consumption . Environmental protection.

<

| Type | Unit | DK7725M | DK7732M | DK7740M |

| Travel | mm | 320X250 | 400X320 | 550X400 |

| Max. cutting thickness | mm | 260 | 260 | 360 |

| Max. tapper | °/mm | 10°/60mm | ||

| Diameter of Mo.wire | mm | Ø0.13-0.18 | ||

| Wire speed | m/min | Variable speed, the fastest is 600m/min | ||

| Net weight | kg | 1500 | 1700 | 2200 |

| Dimensions | mm | 1730X1650X1900 | 1900X1750X1900 | 2200X1860X2200 |

| Max size of workpiece | mm | 500X400 | 580X500 | 780X600 |

| Max. load weight | kg | 250 | 350 | 500 |

| Filter fineness | mm | 0.005 | ||

| Capacity | 110 | |||

| Manner | Differential pressure filtration system | |||

| Max. cutting efficiency | mm2/min | 200 | ||

| Best surface roughness | μm | Ra≤0.8 | ||

| Max. machining current | A | 6 | ||

| Power supply | 380V / 3phase | |||

| Condition | Temperature:10-35℃ Humidity:3-75%RH | |||

| Power | kw | 2 | ||

Product detail pictures:

Related Product Guide:

HESCO Bonefrog Challenge Archives | Cnc-Controlled Flatbed Lathe

How Chloe Kim Won Gold With a Nearly Perfect Score in Halfpipe | Jyp260

Innovation, good quality and reliability are the core values of our enterprise. These principles today extra than ever form the basis of our success as an internationally active mid-size organization for High reputation Lathe Cs6240 - CNC EDM wire cutting machine DK7725M DK7732M DK7740M – Hoton , The product will supply to all over the world, such as: Portugal, Japan, Croatia, We welcome an opportunity to do business with you and hope to have pleasure in attaching further details of our products. Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!