Discount wholesale Hydraulic Bending Brakes - Magnetic Chuck HT series – Hoton

Discount wholesale Hydraulic Bending Brakes - Magnetic Chuck HT series – Hoton Detail:

WITHOUT PUMP:

A. this product adopts vacuum ejector, only through compressor can work.

B. even machine had inhaled cooling oil. cooling water or rubbish etc. Vacuum Chuck also can exclude them.

2. FOR AVAILABLE ALL PROCESS PRODUCTS:

A. work well for up layer process, grinding.

B. assist metal using, special shape produets process also easy to drill work.

3. AT WILL TO ADJUST SIZE:

A. according to size of process products to change assemble and adjust machine.

B. according to process products size to place station.

4. PLACE OF KEY THROUGHAND WORKS TOPPER:

A.vacuum chuck of bottom install key through, so can get exact parallel angle and vertical angle.

B.vacuum chuck of side install two works stoppers, prevent from momentum.

5.FOLLOWING ARE SUITABLE FOR CLAMPING PROCESS:

A. light metal, hard metal, iron board etc.

B. plastic products, ceramics, glass, alminum steelless, wood stone materials etc. All un-magnetic products and un-ventilation smooth products.

C. products of small shape, smooth and complicated process.

D. products of outside need full process will cause scar crooked, curved.

F.products of supper thin can’t clamp.

|

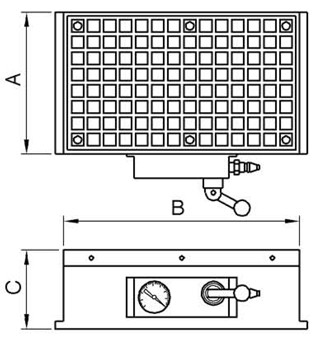

Model no. |

Outline dimensions(mm) |

Air consume (L/min) |

Max suck (L/min) |

N.W.(KG) |

||

|

Lenghth(A) |

Width(B) |

Height(C) |

||||

|

HT1515 |

150 |

150 |

50 |

23 |

12 |

9.2 |

|

HT1530 |

150 |

300 |

50 |

23 |

12 |

13.7 |

|

HT2020 |

200 |

200 |

50 |

46 |

24 |

12.1 |

|

HT2040 |

200 |

400 |

100 |

46 |

24 |

22.2 |

|

HT2525 |

250 |

250 |

100 |

78 |

40 |

16.4 |

|

HT2550 |

250 |

500 |

100 |

78 |

40 |

30.6 |

|

HT3030 |

300 |

300 |

100 |

23 |

12 |

23.4 |

|

HT3045 |

300 |

450 |

100 |

46 |

24 |

37.0 |

|

HT3060 |

300 |

600 |

100 |

46 |

24 |

48.6 |

|

HT4080 |

400 |

800 |

100 |

92 |

48 |

72.9 |

|

HT40100 |

400 |

1000 |

100 |

92 |

48 |

103 |

|

HT5050 |

500 |

500 |

100 |

78 |

40 |

59 |

|

HT5075 |

500 |

750 |

100 |

15 |

80 |

87 |

|

HT50100 |

500 |

1000 |

100 |

15 |

80 |

116 |

|

HT50125 |

500 |

1250 |

100 |

15 |

80 |

145 |

|

HT6060 |

600 |

600 |

100 |

78 |

40 |

87.8 |

|

HT6090 |

600 |

900 |

100 |

15 |

80 |

116.4 |

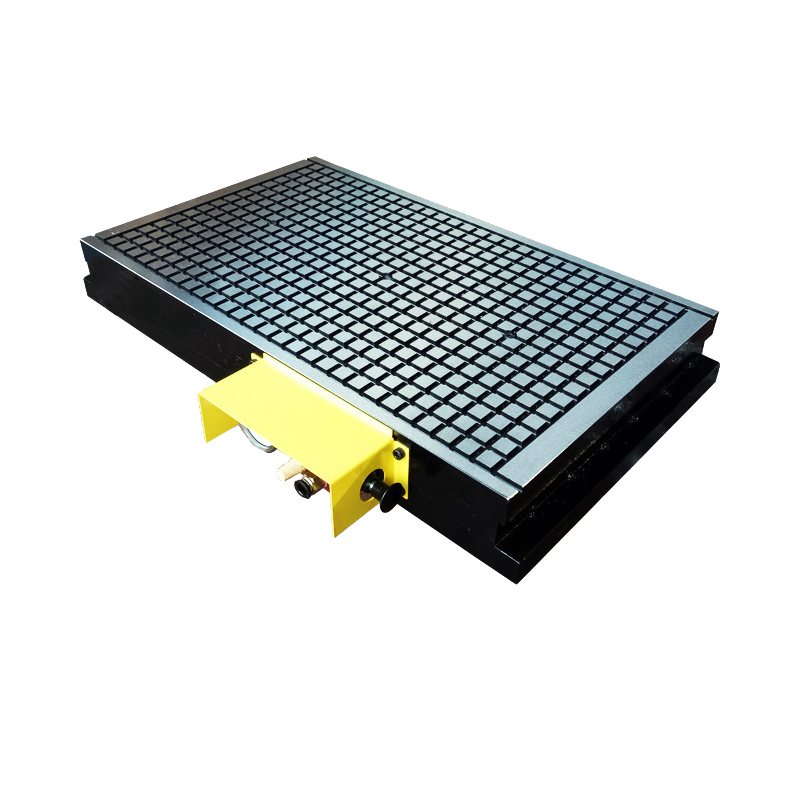

Product detail pictures:

Related Product Guide:

Inventions Competition 2019: Slick fencing kits and one-man wood processors | Shearing Machine

Driving the Digital Revolution with Hydraulic Fluids | Cnc-Controlled Flatbed Lathe

We constantly carry out our spirit of ''Innovation bringing advancement, Highly-quality guaranteeing subsistence, Administration selling advantage, Credit rating attracting buyers for Discount wholesale Hydraulic Bending Brakes - Magnetic Chuck HT series – Hoton , The product will supply to all over the world, such as: El Salvador, Jeddah, Ghana, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We now have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.