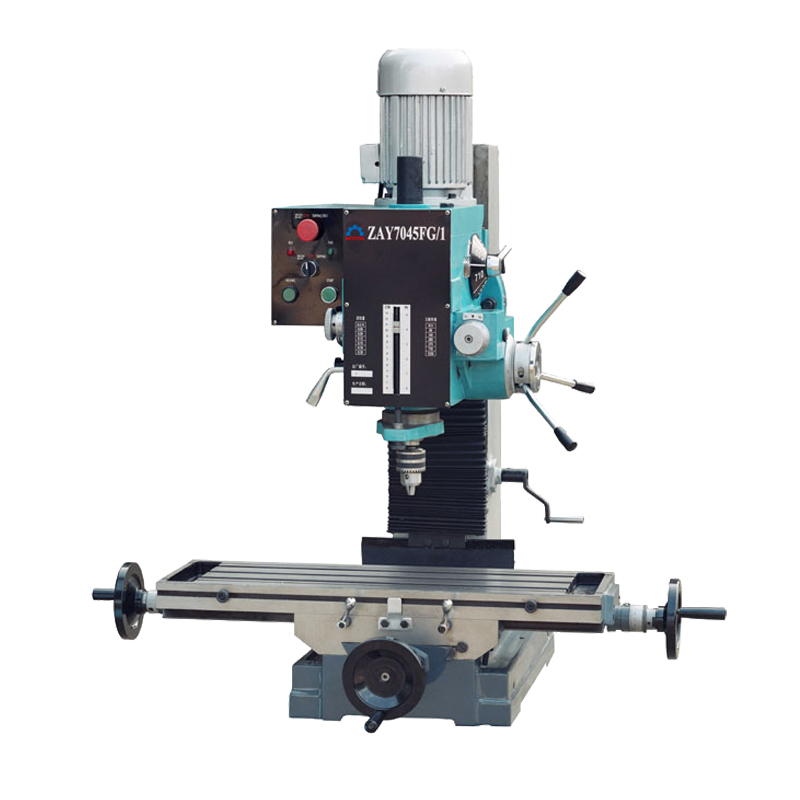

100% Original Lathe Cm6241 - Bench Milling Drilling Machine ZAY7045FG/1 – Hoton

100% Original Lathe Cm6241 - Bench Milling Drilling Machine ZAY7045FG/1 – Hoton Detail:

DRILLING MILLING MACHINE FEATURES:

Spindle speed step-changed cyclically and spindle auto-feeding and cyclic change of feeding speed

And cyclic change of feeding speed

Milling, drilling, boring, reaming and tapping

Head swivels 90 vertical

Micro feed precision

Adjustable gibs on table precision.

Strong rigidity, powerful cutting and precisely positioning.

SPECIFICATIONS:

|

ITEM |

ZAY7032FG/1 |

ZAY7040FG/1 |

ZAY7045FG/1 |

|

Drilling capacity |

32mm |

40mm |

45mm |

|

Max.boring diameter |

50mm |

60mm |

70mm |

|

Max Face mill capacity |

63mm |

80mm |

80mm |

|

Max End mill capacity |

20mm |

32mm |

32mm |

|

Max distance from spindle nose to table |

450mm |

450mm |

450mm |

|

Min distance from spindle axis to column |

260mm |

260mm |

260mm |

|

Spindle travel |

130mm |

130mm |

130mm |

|

Spindle taper |

M.T.3 or R8 |

M.T.4 or R8 |

M.T.4 or R8 |

|

Step of spindle speed |

6 |

6 |

6 |

|

Range of spindle speed 50Hz |

80-1250 r.p.m |

80-1250 r.p.m |

80-1250 r.p.m |

|

60Hz |

95-1500 r.p.m |

95-1500 r.p.m |

95-1500 r.p.m |

|

Auto-feeding step of spindle |

6 |

6 |

6 |

|

Auto-feeding amount of spindle |

0.06-0.30mm/r |

0.06-0.30mm/r |

0.06-0.30mm/r |

|

Swivel angle of headstock (perpendicular) |

±90° |

±90° |

±90° |

|

Table size |

800×240mm |

800×240mm |

800×240mm |

|

Forward and backward travel of table |

175mm |

175mm |

175mm |

|

Left and right travel of table |

500mm |

500mm |

500mm |

|

Motor Power |

0.75KW(1HP) |

1.1KW(1.5HP) |

1.5KW(2HP) |

|

Net/Gross weight |

320kg/370kg |

323kg/373kg |

325kg/375kg |

|

Packing size |

770×880×1160mm |

770×880×1160mm |

770×880×1160mm |

Product detail pictures:

Related Product Guide:

HESCO Bonefrog Challenge Archives | Cnc-Controlled Flatbed Lathe

2007 Audi R8 vs Lamborghini Gallardo vs Porsche 911 Carrera S comparison review: classic MOTOR | Hydraulic Ring Bending Machine

"Quality initial, Honesty as base, Sincere support and mutual profit" is our idea, so as to build repeatedly and pursue the excellence for 100% Original Lathe Cm6241 - Bench Milling Drilling Machine ZAY7045FG/1 – Hoton , The product will supply to all over the world, such as: Philippines, Bogota, Kazakhstan, With well educated, innovative and energetic staff, we are responsible for all elements of research, design, manufacture, sale and distribution. By studying and developing new techniques, we are not only following but also leading fashion industry. We listen attentively to the feedback from our customers and provide instant replies. You will instantly feel our professional and attentive service.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.